Due to confidentiality, I cannot explain every details about my industrial experience on the webpage. If you have any further questions regarding my industrial experience, please contact [email protected].

Bayer HealthcareDiabetes Care

Mechanical/Biomechanical Engineering Intern Summer 2015 | Tarrytown, NY I was able to work as an intern at Bayer Healthcare's Diabetes division. Main roles as a mechanical/biomechanical engineering intern were to design and test the products that were expected to release soon. Since the mechanical engineering team was small, I was able to participate in various mechanical engineering tasks. Summer life at Bayer Healthcare was great and I was able to learn from wonderful colleagues, not just in the mechanical team, but from overall diabetes division. |

Design

|

I was assigned to come up with prototype designs of Bluetooth companion for ContourNext, one of Bayer's self-monitoring glucose meter devices. I conducted design reviews every week to my project manager (Eugene Prais) and senior mechanical engineers (Nihir Patel and Jen Gass) and presented updated designs based on the feedback from previous reviews.

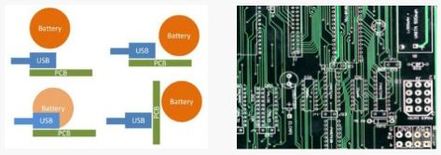

I cooperated with the electrical engineering team and figured out requirements and specifications regarding the printed circuit board (PCB) designs and electrical components, such as micro USB ports, push buttons, and LED diodes. I optimized the mechanical design and the configuration of the electrical components of the Bluetooth companion. I also reached out to human factors team for better design in aesthetics and user experience. It was a good chance for me to learn to work in cross-disciplinary teams. |

Testing

|

Another task assigned to me was to devise protocols and fixtures for the upcoming version of the Microlet 2, Bayer's Lancing device. Referring to the past protocols from Microlet 2, I came up with three protocols: for lancet insertion, priming, and button actuation. I designed individual fixtures for each protocols using SolidWorks CAD software. Then, I 3D printed fixtures via Viper Si2, the stereolithography (SLA) system.

During the priming test, I discovered the thickness discrepancy of sliding barrel end bump between the actual prototype and the CAD model by using MicroVu Vertex 420 and its metrology software. I instantly brought up the issue to Nihir Patel, the corresponding project manager. He confirmed my discovery. Then, we communicated with international manufacturers in Taiwan and Sweden. |

Software Skills