Clutch Lever

The clutch lever is the interface between the driver and the clutch in the engine. The clutch is used in order to engage and disengage the power transmissions.

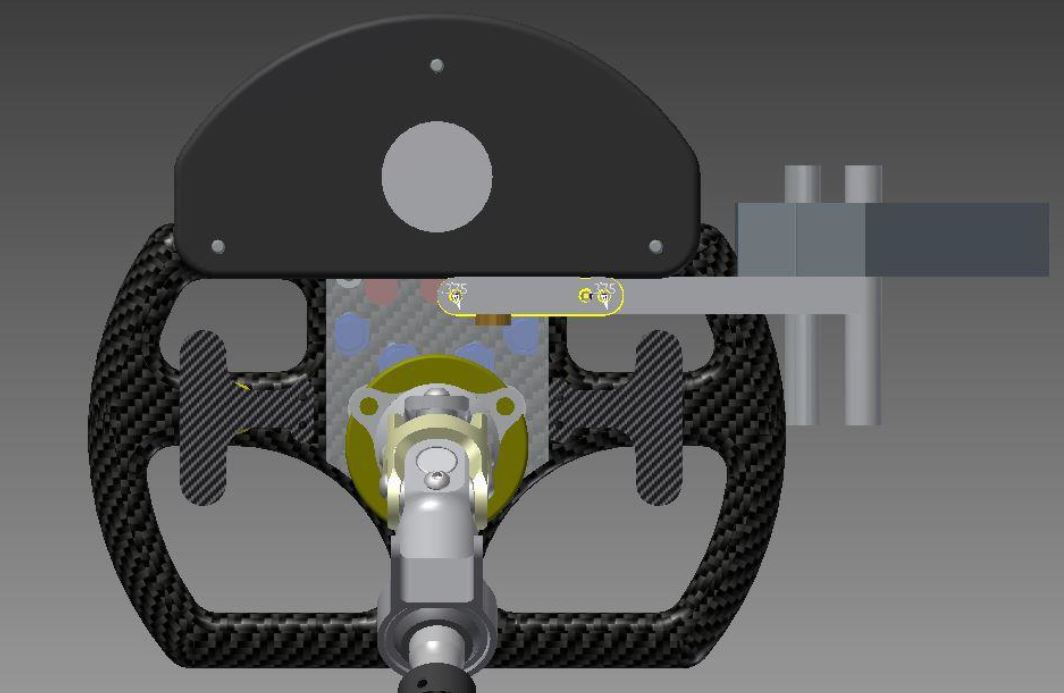

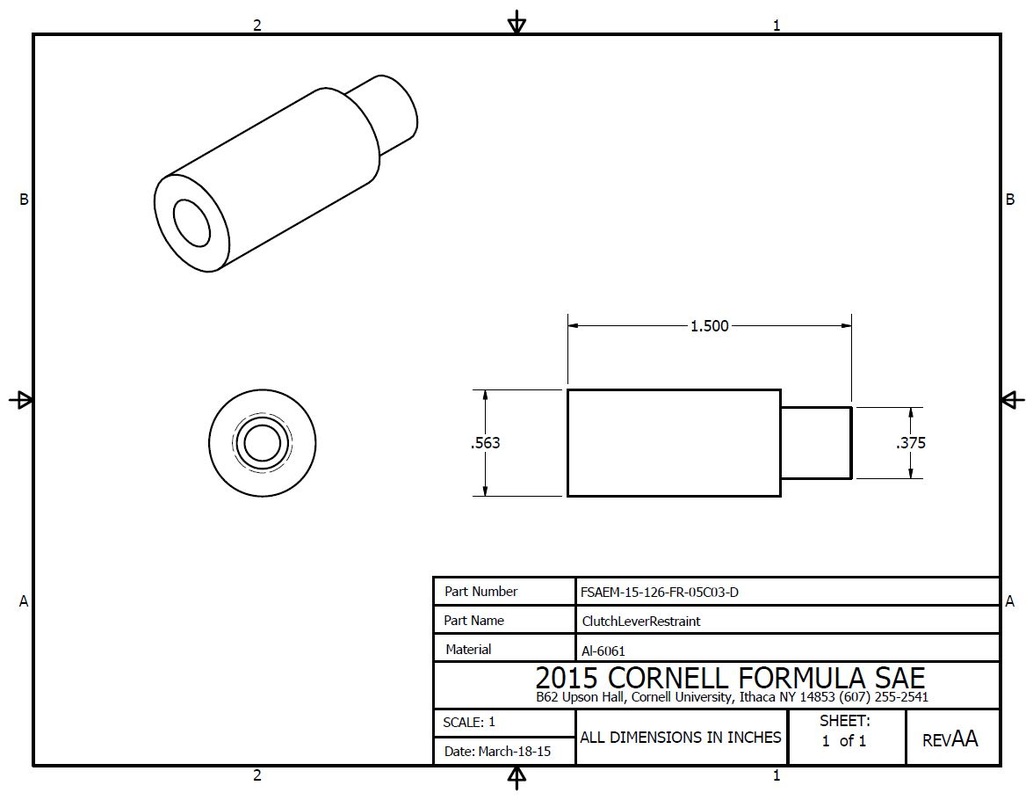

The clutch cable was routed through a machined cable restraint. This restraint was be mounted on the steering lip with an epoxy and align with the hole in the clutch lever. With the cable restraint, we adjusted where the cable will separate from its cover. This method allowed easier installation on the car as well.

After the annual competition, there was positive feedback from drivers that the design of the clutch lever was done well. It was easier for the drivers to grip the lever with the T-shaped handle and the mechanical advantage has helped them to engage and disengage easily.

The clutch cable was routed through a machined cable restraint. This restraint was be mounted on the steering lip with an epoxy and align with the hole in the clutch lever. With the cable restraint, we adjusted where the cable will separate from its cover. This method allowed easier installation on the car as well.

After the annual competition, there was positive feedback from drivers that the design of the clutch lever was done well. It was easier for the drivers to grip the lever with the T-shaped handle and the mechanical advantage has helped them to engage and disengage easily.

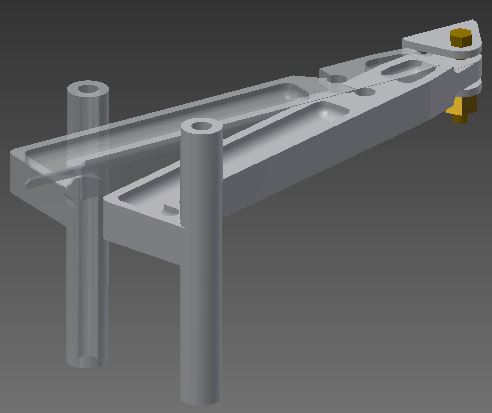

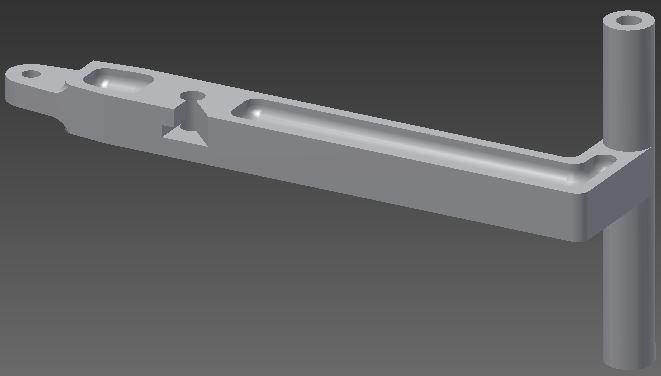

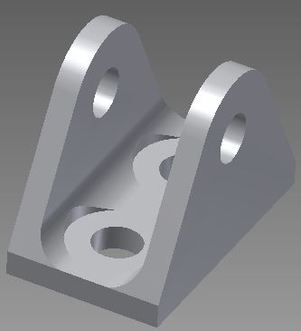

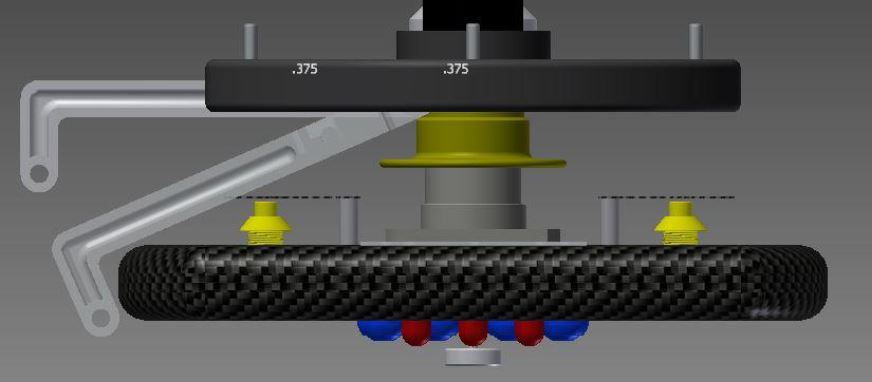

CAD Model & Specs

|

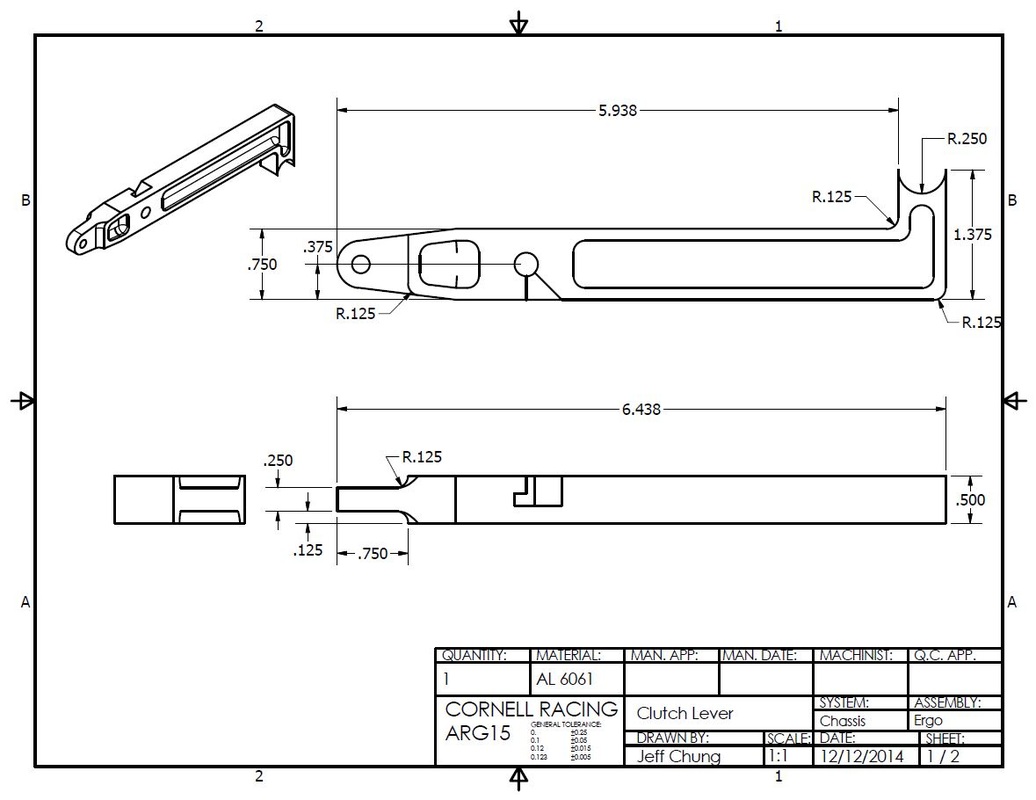

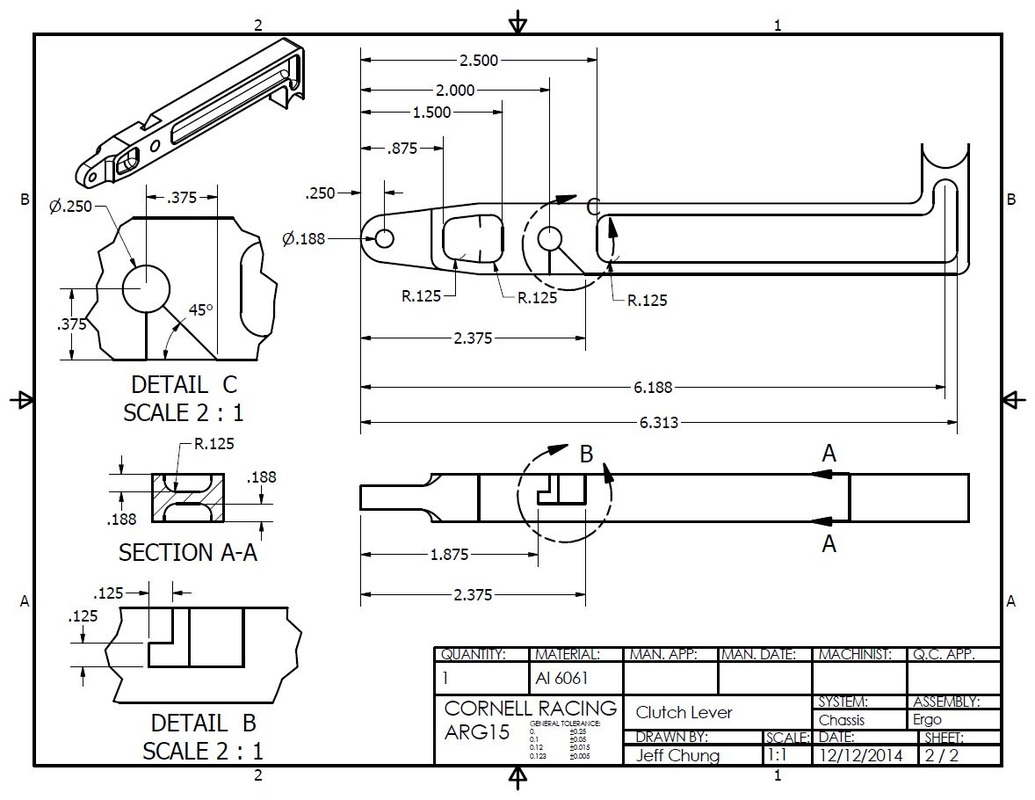

Dimensions

|

|

Design Information

|

Goals

|

Parameters

- The pulling length of the clutch should be the same or longer than the displacement of the clutch in the engine.

- The pulling force of the driver should be the same or larger than the force required to actuate the clutch.

- There should be enough clearance space for the driver's hand to pull the lever with his/her gloves on.

|

Optimization Processes and Decisions

|

Need-to-know Facts

|

|

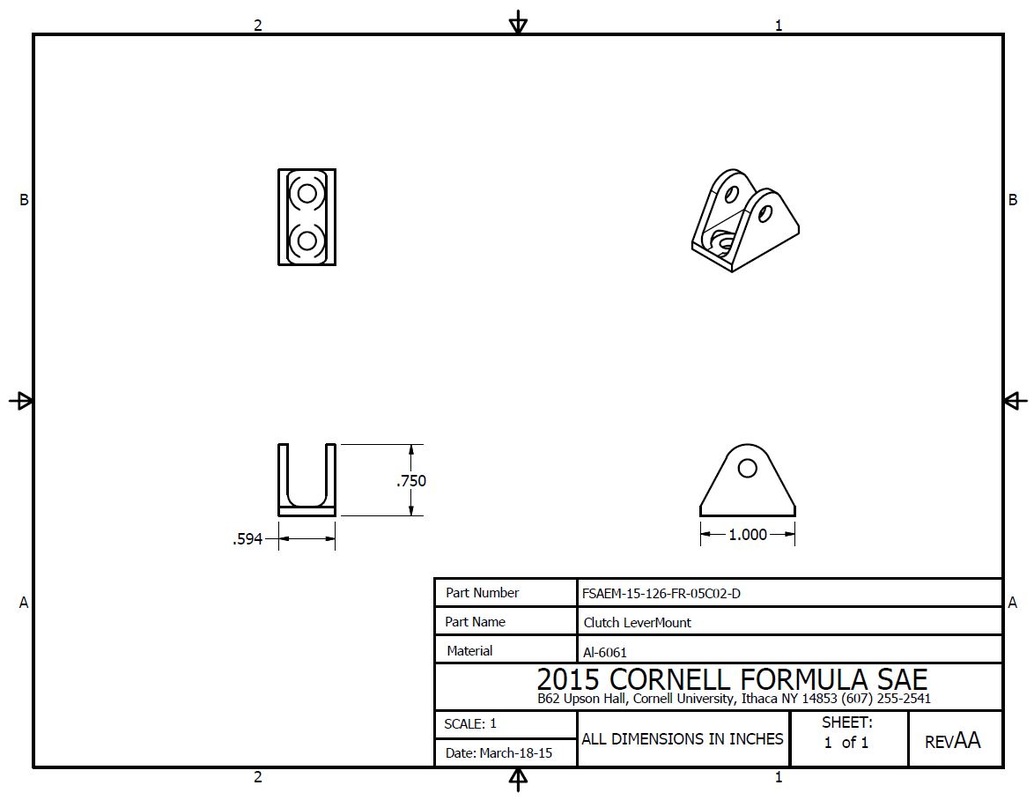

Manufacturing Drawings

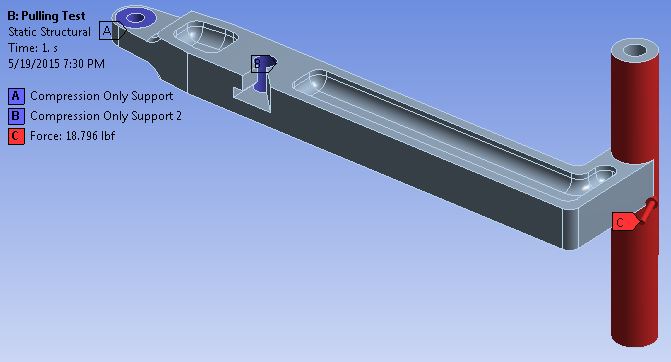

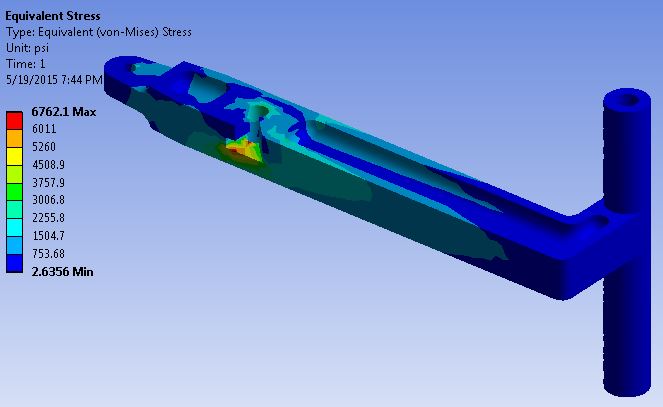

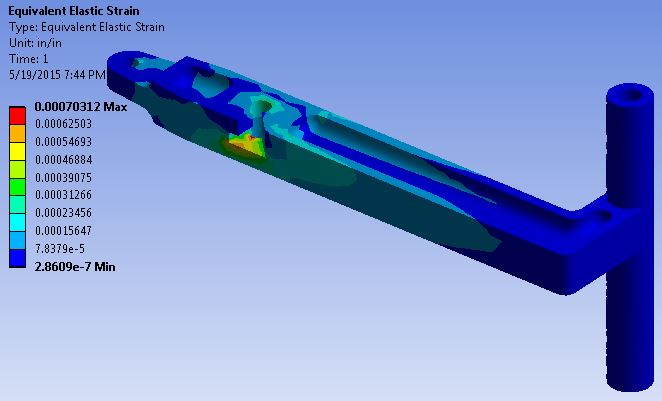

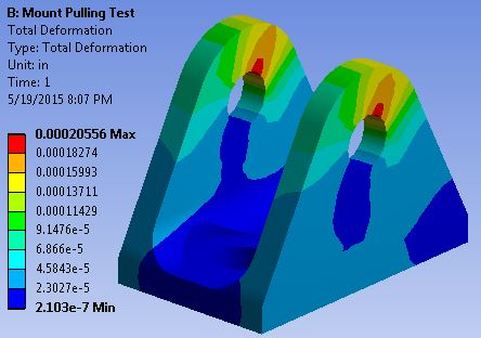

Simulation

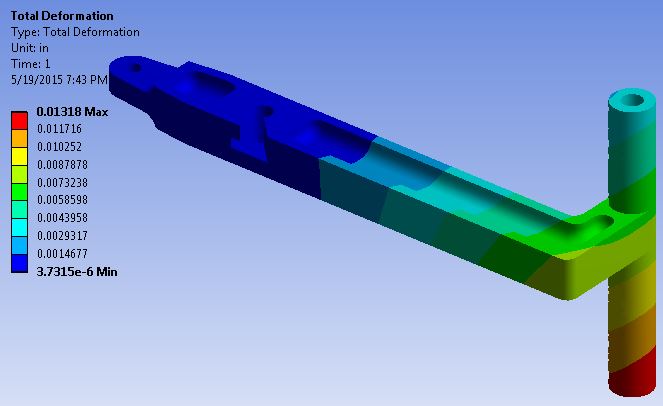

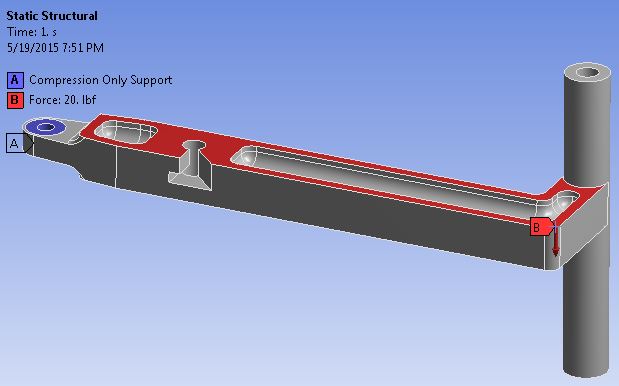

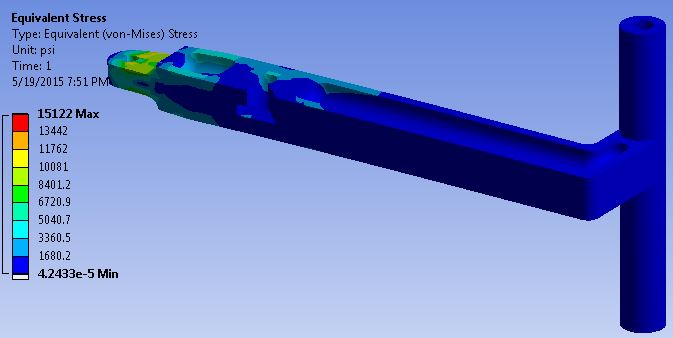

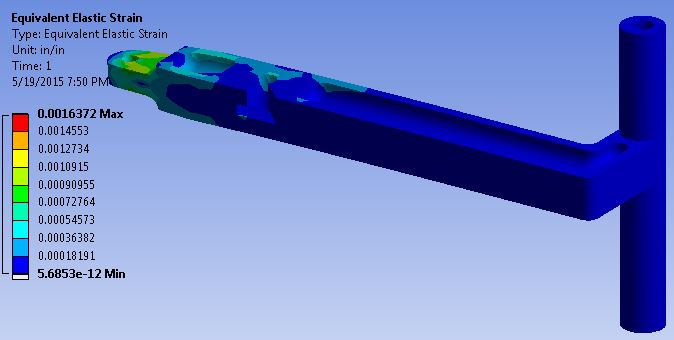

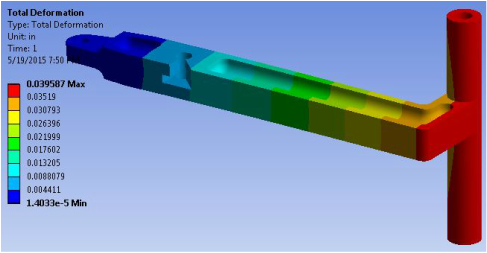

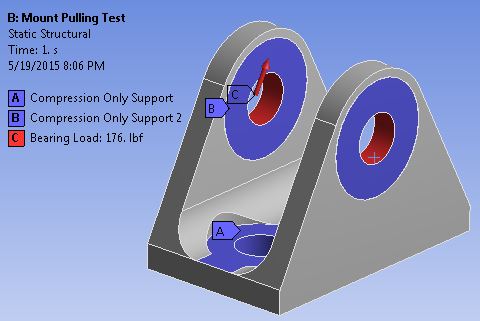

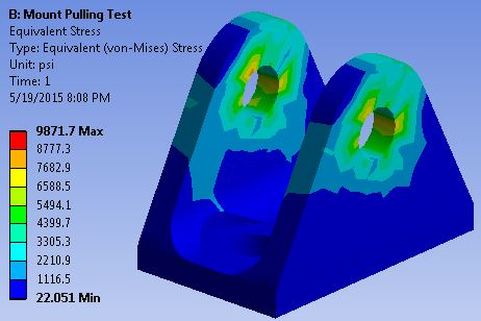

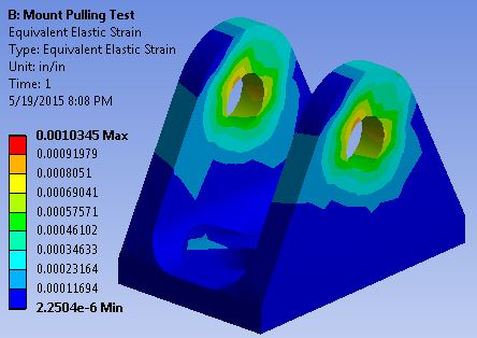

- Lever Pulling Test

- Lever Bending Test

- Clevis Pulling Test

Point Analysis

The length of the lever is designed that it has a good amount of mechanical advantage. The mechanical advantage of 3.4 should allow the driver to pull the clutch lever with no difficulty. The driver only pulls 20 lb of force.

The lever is designed in T-shape and is behind the steering wheel so that whenever the driver need to reach for the lever, it is hard to miss it. When there is a T-shaped handle, a person naturally puts his/her index finger on the upper part of the lever and puts rest of fingers on the lower part of the lever. By gripping in such way, there is less torque generated around the other axis. If the lever was L-shaped like ARG13, then a torque from minor axis will be generated, which does no good but deforms the lever in terms of torsion.

The driver will be reaching for the lever by not reaching his/her hand, but with fingers. Finger size of each person should not differ greatly. There is about two inch space behind the steering wheel. An average person's fingers are longer than two inches, so there should be no difficulty for different drivers, unless the driver's hand is huge.

Moreover, the retention method for the cable is much simpler compared to ARG13. ARG 13 used a coupling nut and two opposing drilled and slotted bolts. The installation of ARG13 clutch lever became an issue due to complexity. The clutch lever design for ARG15 is much simpler with a cable restraint. The cable restraint serves a wall for the cable cover to be fixed while the cable wire is pulled.

The lever is designed in T-shape and is behind the steering wheel so that whenever the driver need to reach for the lever, it is hard to miss it. When there is a T-shaped handle, a person naturally puts his/her index finger on the upper part of the lever and puts rest of fingers on the lower part of the lever. By gripping in such way, there is less torque generated around the other axis. If the lever was L-shaped like ARG13, then a torque from minor axis will be generated, which does no good but deforms the lever in terms of torsion.

The driver will be reaching for the lever by not reaching his/her hand, but with fingers. Finger size of each person should not differ greatly. There is about two inch space behind the steering wheel. An average person's fingers are longer than two inches, so there should be no difficulty for different drivers, unless the driver's hand is huge.

Moreover, the retention method for the cable is much simpler compared to ARG13. ARG 13 used a coupling nut and two opposing drilled and slotted bolts. The installation of ARG13 clutch lever became an issue due to complexity. The clutch lever design for ARG15 is much simpler with a cable restraint. The cable restraint serves a wall for the cable cover to be fixed while the cable wire is pulled.