Organic Robotics Lab (ORL)

This is where I learned about the life of a researcher at Cornell. Descriptions about my tasks and projects are included in the Portfolio Category. If you want detail information that are not explained in the Portfolio category, please email [email protected].

The Organic Robotics Lab (ORL) focuses on using synthetic adaptation of natural physiology to improve machine function and autonomy. Our research spans three primary areas: bioinspired robotics, soft sensors and displays, and advanced manufacturing. We use soft materials, mechanical design, and novel fabrication methods to replicate sensory organs such as dermal papillae, replicate organs that rely on actuation such as the heart, and to power soft actuators and robots.

- excerpted from ORL webpage

ORL Research Areas

Bioinspired MachinesOur primary research thrust is the design, fabrication, and optimization of soft actuating systems for applications in robotics and human interface and assistive technologies.

|

Sensors & DisplaysWe develop electronic sensors and visual displays from purely soft materials (elastomers, hydrogel, embedded hard components) for soft robotics, prosthetics, and wearable devices.

|

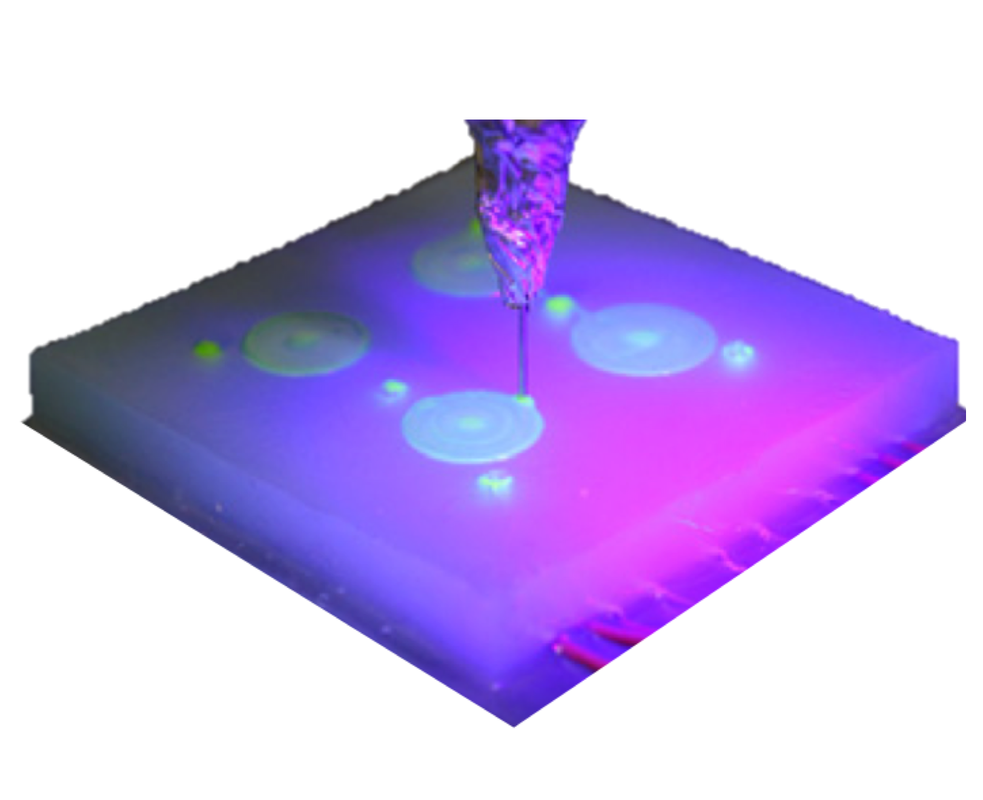

Advanced ManufacturingWe develop advanced methods based on direct ink writing, digital mask projection stereolithography, conformal lithography, and rotational molding to fabricate soft robots, wearable devices, displays, and sensors.

|

- excerpted from ORL webpage.

For more details, please visit orl.mae.cornell.edu.

For more details, please visit orl.mae.cornell.edu.

My research areas at ORL

Bioinspired Machines

|

Soft Orthotic Actuators

We applied rotational casting as a reliable and effective method for fabricating high force orthotics. We fabricated a wearable assistive device for increasing the force a user can apply at their fingertips. To better improve the functionality of the hand orthotics, we also demonstrated the monolithic integration of solid-state optical light-guides for curvature sensing in them. Besides fabrication and integration, we have also realized feedback control of FEAs using the embedded sensors.

|

|

|

Bicontinuous Liquid Metal Foams

We have developed a composite of two entangled foams: an elastomer and a low melting temperature metal, that exhibits dynamic shape morphing and shape memory actuation. Additionally, by melting and freezing the metal foam, the composites can both self-heal and be assembled into larger, continuous structures from smaller sub-components. The composite has been embedded into two soft robotic devices to demonstrate the capability for reversible stiffness in soft robots. |

|

Advanced Manufacturing

|

Rotational Molding

We've adapted an industrial scale fabrication technique called rotational casting to fabricate monolithic soft actuators from thermosetting elastomers. A major advantage of this method is that no adhesives are required this results in the ability to apply higher forces compared to other soft actuators that are bonded, and the potential to use tougher materials (e.g., polyurethane, styrenebutadiene). Rotational casting will expand the applications of soft robots, especially those requiring high force, high volume production, and high reliability.

|

|

- contents and videos excerpted from ORL webpage.